What does an engraving machine for bells look like?

Our customers often ask us how bells are engraved and what kinds of machines are used. We would love to give you an insight into the craft of bell engraving.

In answering this question, you should know that there is not a single machine that delivers a full bell engraving, but that it takes a lot of experience to engrave a bell professionally.

Therefore, the engravings offered by us are offered by master craftsmen, who have years of experience and on whose work we can thus rely on.

There are devices that help with engraving bells, but labelling these bells is a craft, because bells are three-dimensional objects and the engraving surface is not simple a plane.

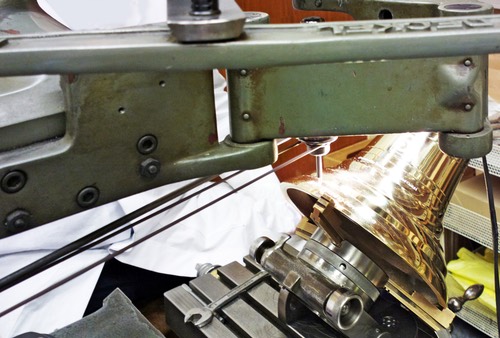

For a professional engraving, it is therefore necessary to clamp the bell in a holder which can rotate during the processing of the bell. This fixture is called a partial head and should be available in various sizes for different bell sizes. Thus, for each engraved letter to be engraved in the same size proportionally speaking, the engraving surface must be accurately rotated below the engraver. The rounding of the bell must be compensated for by a tilting device on the tool holder so that the letters are perfectly aligned later on.

If this were not so, the letters at the beginning and in the middle of the label would be engraved in an incorrect size. Therefore, the special holders described above are required in order to make for a single typeface.

For the actual engraving, the engraver prepares the font on a lettering stencil.

Once this stencil is available, the engraver places a scanner on the lettering stencil with one hand, while the engraver guides the rotating cutter across the bell with his second hand. By exerting varying amounts of pressure on the cutter, the engraver can affect the width of the text and logo engraving. Engraving a harmonious typeface with the wedge-shaped carved cutter requires a lot of experience. Given their 3D shape, bells are thus a supreme discipline for the engraver.

In these pictures, you can see a bell with a diameter of 30 cm (Art. 2219) on a professional engraving machine during the labelling process for one of our clients.